Save $200 - Register & pay by December 31

Are you ready for hands-on training that will teach you more about your Uninterruptible Power Supply (UPS) system and stationary batteries? Our four-day UPS and Stationary Battery classes at our Texas training facility are the perfect place to expand your knowledge.

Each of our training courses is customized to simulate the applications and assets in your facility. As a participant, you will see how these systems work, learn troubleshooting tips, monitoring and routine maintenance. Our experienced instructors provide hands-on and real-world learning so you leave with the knowledge and skills necessary to troubleshoot your systems safely and with confidence.

Participants will receive 2.4 Continuing Education Units (CEUs) upon completion. Click here to learn more about our Ferroresonant and Digital Process Power UPS System and Stationary Battery training.

| 2022 Dates | Location | Class |

|---|---|---|

| March 21-24 | Houston | Digital Process Power UPS & Stationary Battery |

| April 4-7 | Houston | Ferroresonant UPS & Stationary Battery |

| May 16-19 | Houston | Digital Process Power UPS & Stationary Battery |

| August 8-11 | Houston | Ferroresonant UPS & Stationary Battery |

| August 15-18 | Houston | Digital Process Power UPS & Stationary Battery |

| September 26-29 | Houston | Digital Process Power UPS & Stationary Battery |

| October 17-20 | Houston | Ferroresonant UPS & Stationary Battery |

| November 14-17 | Houston | Digital Process Power UPS & Stationary Battery |

| December 5-8 Nuclear | Houston | Nuclear Class 1E Safety Related Analog Systems |

Space is limited and this deal won't last forever,* so register today!

*Register and pay for a 2022 training class by December 31, 2021 and receive the 2021 pricing; a savings of $200 per attendee! All classes must be paid in full by December 31, 2021 for the 2021 pricing to be honored. Payments after December 31, 2021 will be subject to the 2022 pricing effective on January 1, 2022.

nVent RAYCHEM is pleased of offer Industrial Heat Trace Design and Optimization Webinars. These free webinars are provided to inform and educate on designing and optimizing heat tracing solutions.

TraceCalc Pro Heat Tracing Design Series: These are 30-minute seminars designed to provide tips and tricks for using TraceCalc Pro software to design heat trace projects.

| Date/Time | Topic | Webinar Link |

|---|---|---|

| May 4, 2021 1:00PM CDT | Introduction to TraceCalc Pro | View Recording |

| May 25, 2021 1:00PM CDT | Reports and BOM Development | View Recording |

| June 15, 2021 1:00PM CDT | Plastic Pipe Design and Cable Results | View Recording |

| July 6, 2021 1:00PM CDT | Insulation Types - Superseded and Current | View Recording |

| August 3, 2021 1:00PM CDT | Parent / Child Design | View Recording |

| September 7, 2021 1:00PM CDT | Control Methods Impact on Design | View Recording |

Informative Webinars: These are 60-minute sessions designed to provide insights on various topics to help maintain industrial facilities.

| Date/Time | Topic | Webinar Link |

|---|---|---|

| August 24, 2021 1:00PM CDT | Introduction to TraceCalc Pro | View Recording |

| September 28, 2021 1:00PM CDT | Reports and BOM Development | View Recording |

For more information about nVent thermal webinars, visit www.nvent.com/thermal-webinars.

The GEN 2 features a hardened design

for extreme environments. Engineered

for years of durability and reliable

performance in corrosive environments

with minimal maintenance.

This extended warranty provides the RGA

750 GEN 2 not only the technology edge

for a retractable bonding cable, but also

provides LEC’s RGA a product warranty

edge over our worldwide competitors.

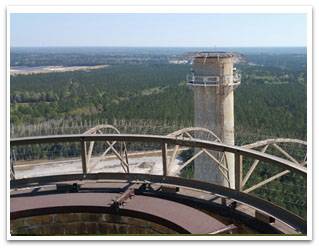

Approximately 30% of all tank fires and explosions are caused by lightning. Floating roof tanks are particularly vulnerable to lightning. These can be prevented by using Lightning Eliminators Retractable Grounding Assembly, the RGA 750 Gen 2.

Contact us to learn more. sales@engineeredequip.com

Over 1,300 North Arkansas Electric Cooperative customers served by the Norfork Substation are still without power following a lightning strike Sunday night.

At the peak of the outage, over 4,000 customers were affected. The Norfork Substation is located below Norfork Dam.

Microsoft was scrambling to get a number

of cloud-based services up and running this

morning, after a lightning strike near one of

its San Antonio data centers caused a voltage surge. This in turn forced a power-down when cooling equipment failed, triggering an Azure outage and global Office 365 outages.

NASA has been using LEC to protect their towers and has had no lightning strikes in over 20 years.

Georgia Pacific has been using LEC to protect their chemical stacks for over 20 years with no strikes.

Questions? Contact sales@engineeredequip.com

Pepperl+Fuchs' latest collaboration with Samsung–the Ex-Cover Pro D2–is now shipping! The latest addition to the P+F mobility lineup adds another piece of the puzzle to our mobile worker platform, making it easier than ever to find the perfect device for your application. The Ex-Cover Pro D2 utilizes the same slim and lightweight design as the original Samsung device, giving workers a lightweight and easy-to-carry option in a Division 2 certified smartphone designed to stand up to the toughest conditions. It is also certified for use with Verizon and AT&T’s carrier-integrated Push-To-Talk services.

The Ex-Cover Pro D2 is a perfect fit for a wide range of applications for customers in Oil and Gas, Petrochemical, Pharmaceutical, and Food Processing, or any other industry with classified areas. The integrated Push-To-Talk keys eliminate the need to carry radios in the field by replicating that functionality on a modern platform that is capable of much more than simple communication. With a wide range of third-party apps available, field workers can use devices like the Ex-Cover Pro for everything from process monitoring and visualization to asset tracking. Inspection reports, work reports, work procedures, and even data collection for reliability monitoring can all be easily digitized for increased efficiency and accuracy.

The Ex-Cover Pro D2 is rated for Class I, Division 2 hazardous areas, and is in stock now.

For more details on the features and specifications of the Ex-Cover Pro D2, we have provided you with both a brochure and a video.

If you are interested in receiving a demo device of the Ex-Cover Pro D2, contact sales@engineeredequip.com and ask about our demo program.

Protecting the health and safety of the workforce should be the number one priority for site managers. With a Hughes site survey our safety shower and eye wash expert will inspect your facility to ensure you have the most suitable equipment, in the right location and ensure they are functioning as per ANSI guidelines. On average, we can cover around 50 showers per 8-hour day.

Your dedicated Hughes specialist will complete a 25 point inspection, following ANSI Z3581.1-2014 guidelines, as well as national plumbing codes and OSHA regulations.

Common issues raised following a site survey:

Hughes offers a large range of emergency safety showers and eye/face wash equipment for all locations, climates and challenges:

For more information on scheduling a survey, contact sales@engineeredequip.com